About our Laminating machine factory

We design and manufacture high-performance automatic paper laminating machines that power production lines across packaging, publishing, and printing industries.

Custom Laminating Machines That Fit Your Workflow

In the world of paper lamination, there’s no such thing as one-size-fits-all. That’s why we specialize in manufacturing laminating machines tailored to your specific production needs.

Whether you’re running high-speed packaging lines or short-run specialty prints, we customize core components—motors, belts, pumps, and control systems—to match your output, substrate types, and operational preferences. With flexible engineering and hands-on support, we ensure your machine fits seamlessly into your workflow, optimizing both productivity and product quality.

Whether you’re running high-speed packaging lines or short-run specialty prints, we customize core components—motors, belts, pumps, and control systems—to match your output, substrate types, and operational preferences. With flexible engineering and hands-on support, we ensure your machine fits seamlessly into your workflow, optimizing both productivity and product quality.

Founded

0

Staff

0

Machines Sold

0

Engineers

0

Serving a Wide Range of Industries

Our paper laminating machines are trusted across diverse industries that demand durability, precision, and speed. From packaging and printing to publishing, labels, stationery, and commercial graphics, our solutions are built to handle a wide range of substrates and applications. Whether you’re producing glossy magazines, food-grade cartons, soft-touch brochures, or custom retail packaging, we tailor our machines to meet the unique needs of each sector. With robust engineering and flexible configurations, we help businesses across industries enhance product quality, streamline production, and stay competitive in fast-moving markets.

Your reliable partner for laminating machines

Our laminating machines are engineered for precision, speed, and durability—built to handle high-volume demands with consistent quality. With full customization options, advanced automation, and user-friendly controls, our machines seamlessly adapt to your workflow. Designed for energy efficiency and heavy-duty use, they’re rigorously tested to deliver zero-defect performance. Whether you’re upgrading or expanding, our solutions integrate easily into existing lines, backed by trusted global support and service.

- Precision-Engineered for Long-Term Reliability.

- Fully Customizable to Fit Your Production Needs.

- Advanced Automation for Maximum Efficiency.

- Energy-Efficient Design to Lower Operating Costs.

- Global Service Support with Proven Industry Trust.

Concept & Engineering Design

Every machine starts with a detailed understanding of customer needs. Our engineering team designs the machine layout, lamination path, feeding system, and control logic using advanced CAD and simulation tools. This phase ensures that the final design balances speed, accuracy, and ease of operation—customized for specific materials, outputs, and space constraints.

Material Selection & Procurement

We source high-quality materials and components, including steel frames, chromed or rubber-coated rollers, precision gearboxes, servo motors, belts, heating elements, and PLC control units. All materials are selected based on durability, heat resistance, and mechanical performance to ensure long-lasting and reliable operation.

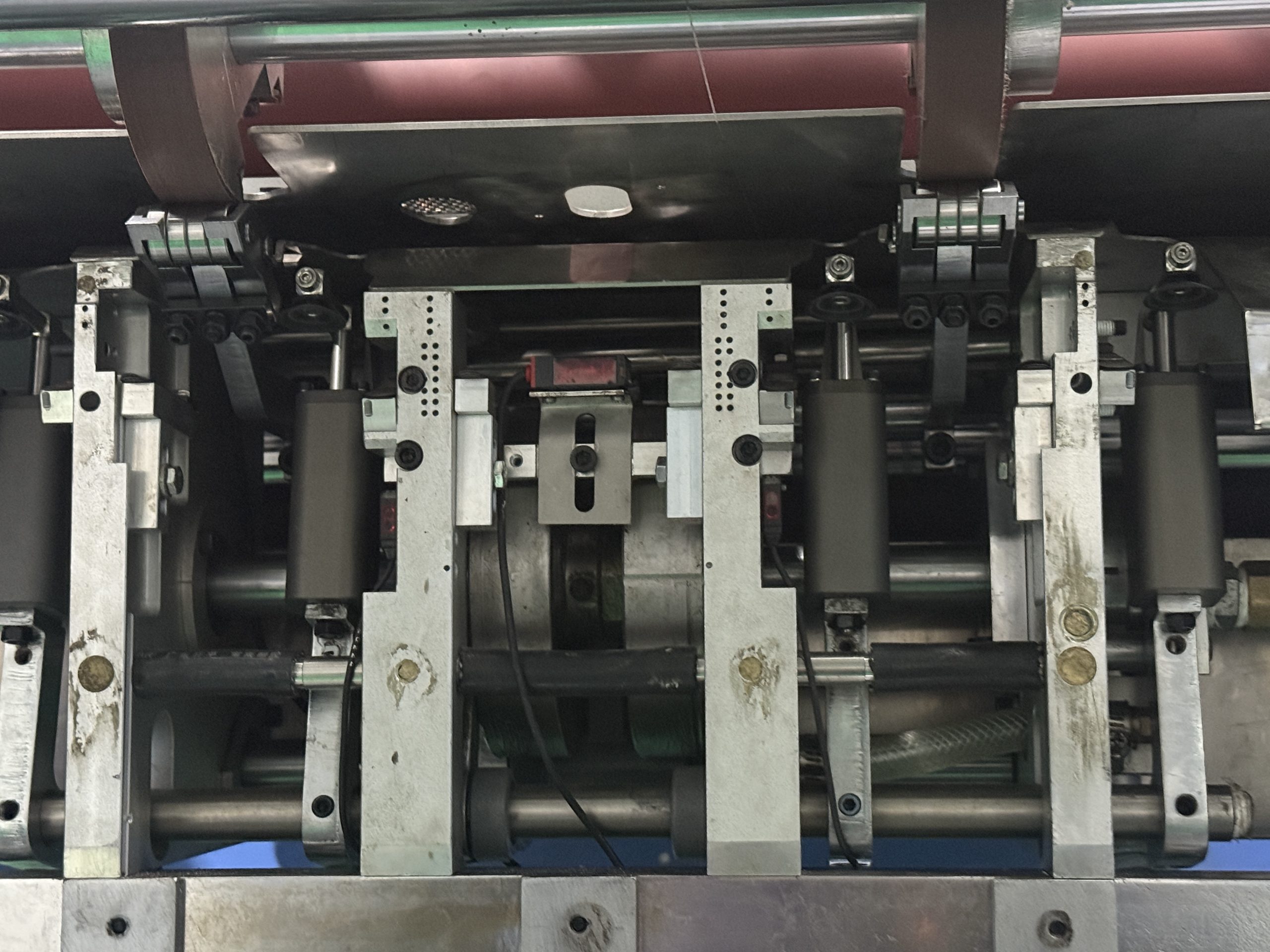

Fabrication of Core Components

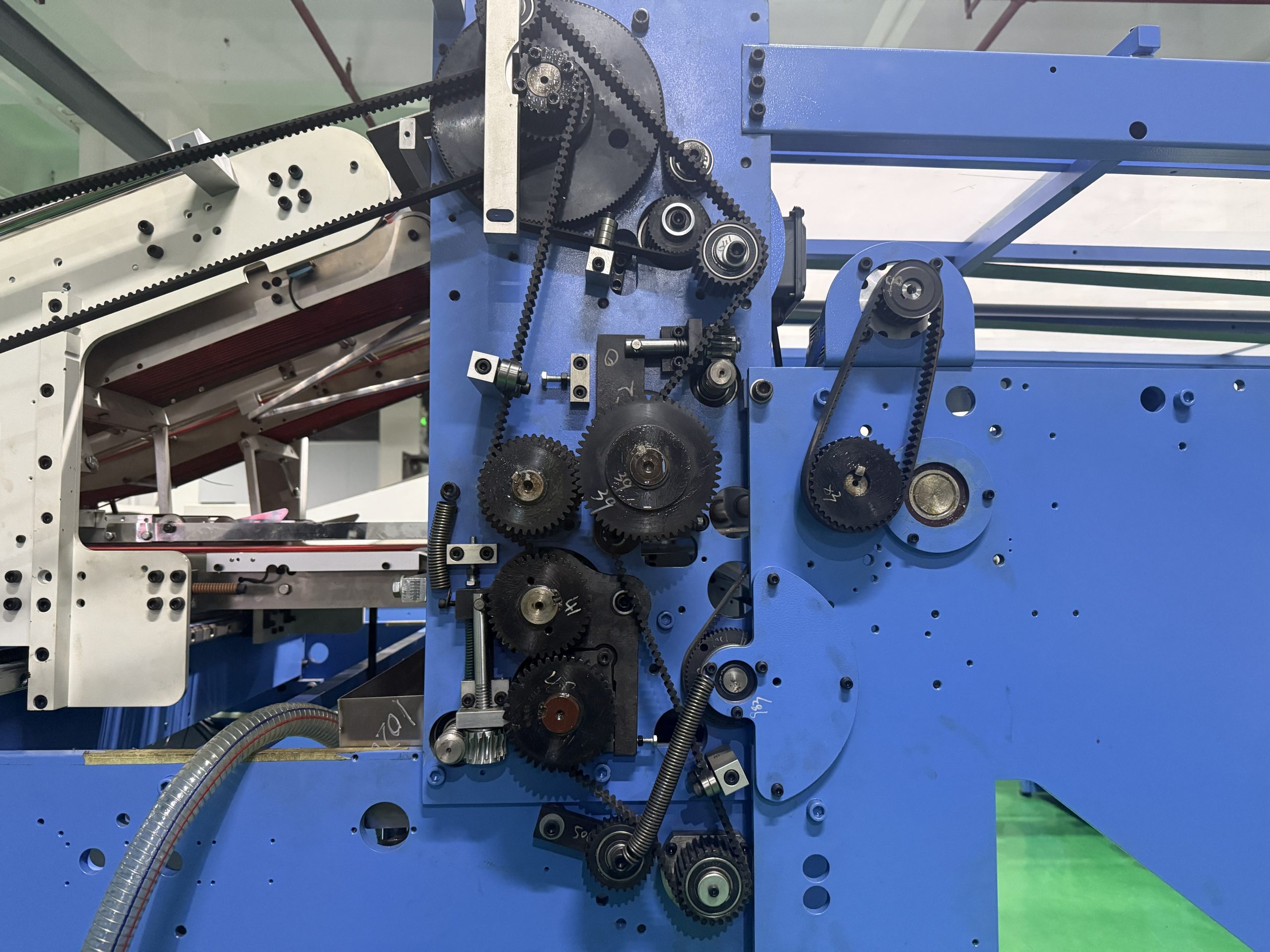

Key mechanical components such as the main frame, rollers, shafts, and mounting plates are fabricated using CNC machining, laser cutting, and welding. Special attention is given to surface smoothness and dimensional accuracy to ensure tight tolerances, which are critical for smooth feeding and lamination quality.

Surface Treatment & Revestimento

After fabrication, parts go through surface treatment processes such as powder coating, polishing, chrome plating, or heat treatment, depending on the function of the component. This step improves corrosion resistance, aesthetic finish, and overall durability, especially for parts exposed to heat or adhesive.

Machine Assembly

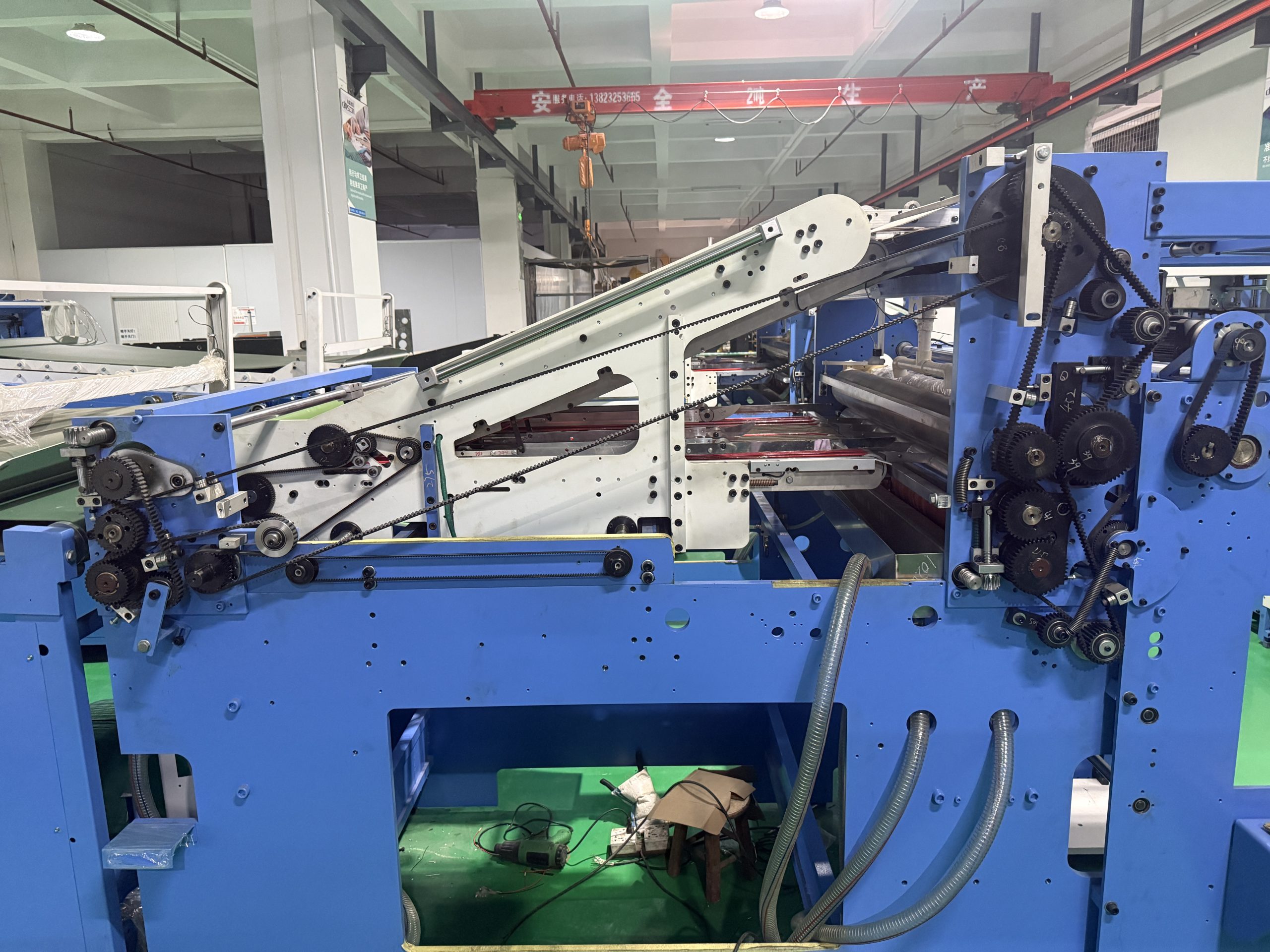

The machine is assembled in stages, starting with the frame, followed by the roller systems, feeder units, glue or thermal systems, and cutting sections. Belts, sensors, and pneumatic lines are also installed. Each component is precisely aligned to ensure accurate substrate handling, minimal friction, and proper tension.

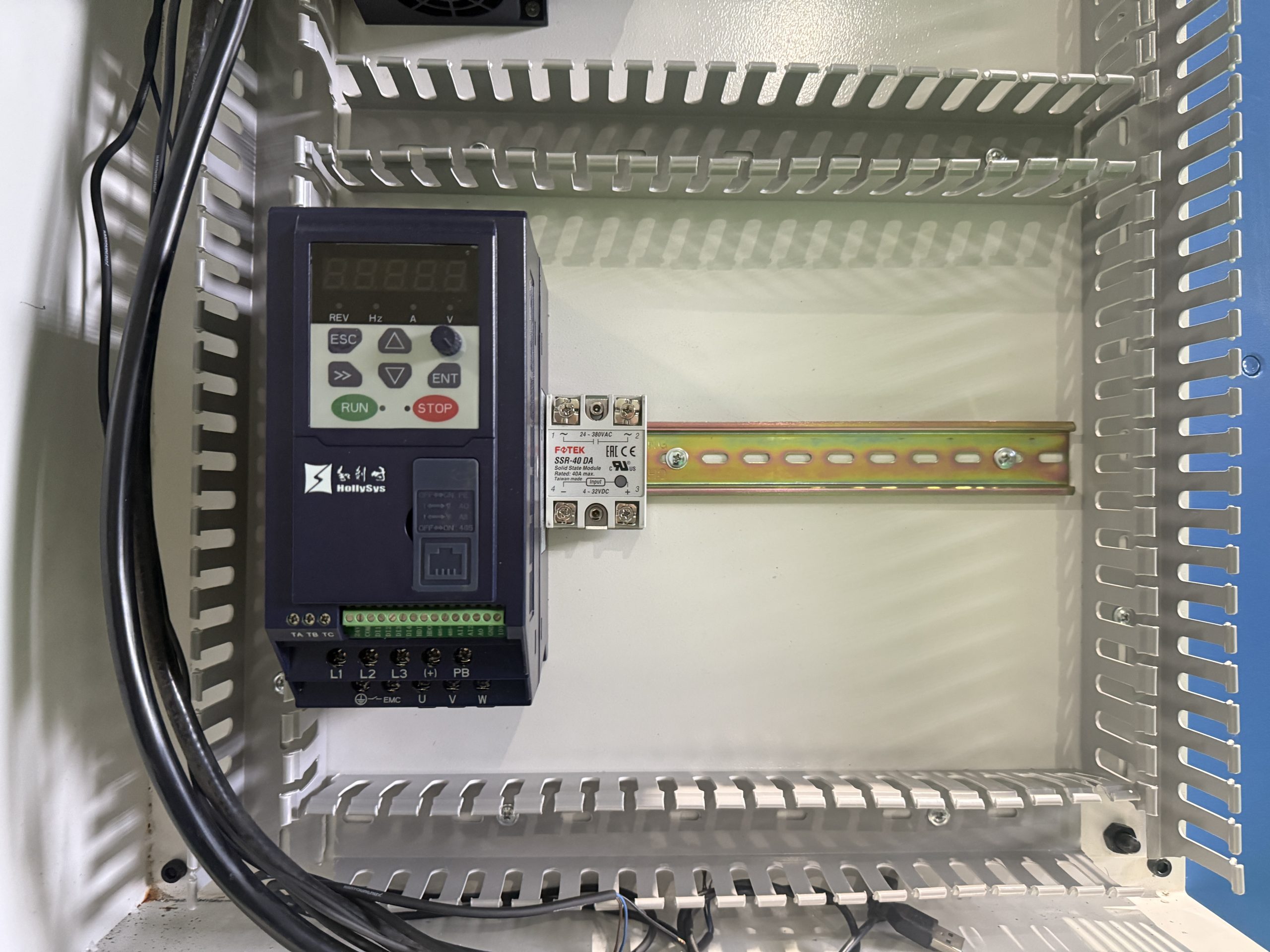

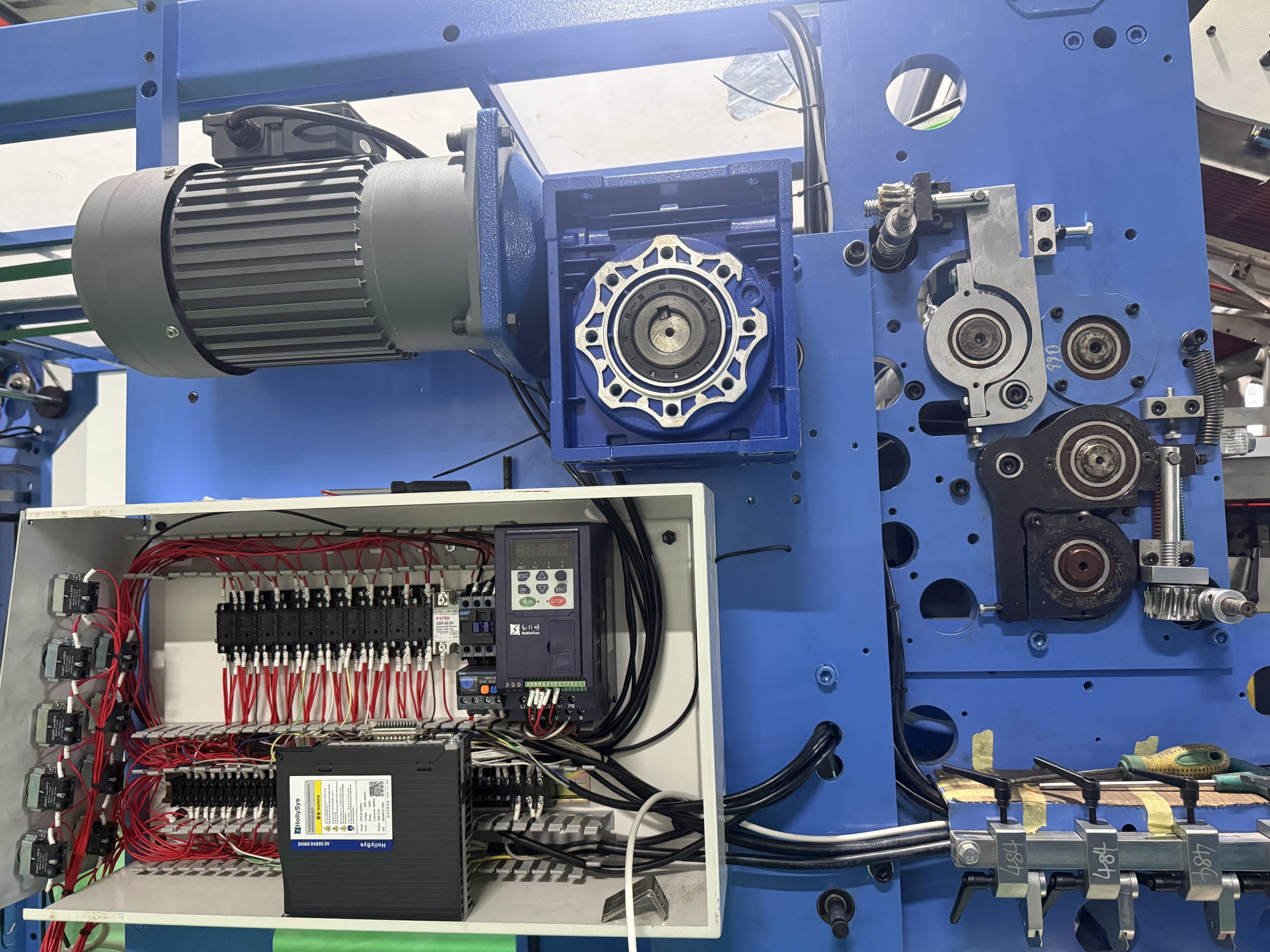

Electrical & Control Integration

Electrical engineers install the motor drives, PLCs, touchscreen HMI panels, temperature controllers, and safety switches. Wiring is routed neatly and safely through control cabinets. The control system is then programmed to manage speed, pressure, temperature, timing, and emergency stops.

Testing & Calibration

Before delivery, every machine undergoes rigorous testing to ensure optimal performance. This includes dry runs, live lamination tests, roller pressure calibration, and temperature checks. We verify that all systems—mechanical, electrical, pneumatic—work smoothly together and meet customer specifications.

Final Inspection & Packaging

Each machine is inspected against a detailed quality checklist, ensuring there are no loose fittings, wiring issues, or cosmetic defects. Once approved, the machine is carefully cleaned, protected with anti-rust coating, wrapped with protective film, and securely packaged in wooden crates for international transport.

Upgrade Your Printing Today!

Take your printing operations to the next level with our premium rubber blankets, designed for maximum performance on any substrate. Whether you’re printing magazines, packaging, or specialty items, our blankets deliver sharp, consistent results every time. Request a free sample, get a customized quote, or talk to our expert team today to find the perfect solution for your printing business. Don’t wait—upgrade your printing efficiency now!

Let’s work together

Durable, Reliable, and Customizable for All Your Offset Printing Needs